Rob Davidson - Maker

Knives From the

Texas Hill Country

Since 1978

830-798-7744

|

Rob Davidson - Maker Knives From the Since 1978 830-798-7744 |

|---|

|

Rocket Knives Tutorials |

|

How-to Make a Liner Locking Folding Knife

|

|

| This page is created for those that have been wanting to know how to go about making a liner locking folding knife. This is a short archive of most of the steps involved with the knifemaking process. |

Please keep in mind that this is only one way out of very many ways to accomplish the same thing. What works for me may not work for you. This is intended as a guide to get started and assist in basic knowledge. Have thoughts or ideas??? Let me know. |

|

| Above shows the finished piece for this tutorial. Scroll down to see the steps taken to make this piece possible. |

|

This is where it all starts. |

This pic shows a closer view of the |

|

|

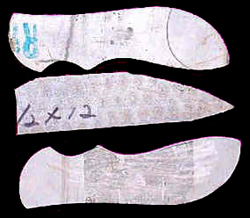

A sheet of .100 thickness titanium. This will be used as the liner/frame for the knife. Notice that there is a pattern next to the sheet. This is the pattern for the medium-sized tactical folding knife and the pattern for this project. |

| Two liners sawn from the titanium sheet above. These liners have already been profiled with the belt sander. This leaves a very smooth outside line and make the frame pieces the same size. |

|

|

Now there are two liners and a |

Before we can continue, the blade needs |

|

|

Blade installed. Two liners and a |

The blade is now notched for the lockbar. |

|

|

The profiled liners with the notched blade. |

Inserted into the vise is a small piece |

|

|

The blade has been profiled and ground. |

Blade coated with a compound to |

|

|

A Note About Heat Treatment |

|

|

Blade heat-treatment. |

| Heat-treated blade. Some of the coating remains, but is easily ground away after tempering. This type of damascus steel will temper @ 400F for 2 hours, put in the freezer overnight and again heated to 400F for 2 hours. The blade is ready for clean-up and the knife will be ready for assembly and final shaping. |

|

|

All parts ready for final clean-up and |

The blade has been cleaned up and all of |

|

|

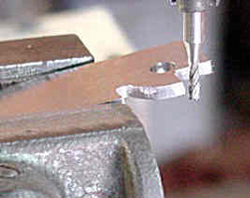

A mark has been made for the place to cut the notch for the lockbar. The short cut across the frame is being made. This is the part of the lock that will rest against the notch in the blade to hold it securely open. Be sure to leave a little "extra" to grind to make a perfect fit. |

| With the short part of the lock cut, we can now cut the length of the frame to finish up the locking bar. This cut is to make the lock flexible and work back and forth inside the blade notch to lock the blade in place and to help to keep the blade shut when it is supposed to be shut. |

|

|

The lock bar cut and fitted. The knife is once again assembled. We can now proceed to make the final grinds and contours to the frame to finish this knife up. The blade still needs final grinding and hand sanding before it is etched to bring out the pattern in the stainless damascus steel blade. |

| After the frame has been contoured, the knife is disassembled to attach the pocket clip. Notice how the clip rests on the lockbar for extra support for the lock. A hole is drilled into the lockbar for the detent ball. The detent ball is used to hold the knife blade shut when the blade is supposed to be shut. A matching hole is drilled into the blade. The blade is hardened, so a diamond drill is used. Just a few thousandths of an inch is plenty. |

|

|

The blade heat-treated, cleaned-up and then etched with ferric chloride. A final polish with 600 grit sandpaper (or finer) bring out the pattern in the steel. The blade is completed and ready for installation into the finished frame. |

| All parts ground, hand sanded and the titanium parts are heat-colored in the heat-treatment kiln. The clip is also heat colored. The thumbstuds are attached by using a shortened threaded shaft screwed into both thumbstuds and the blade. Next step is to assemble the piece and fine-tune. Washers are not shown here, but are necessary!!! |

|

|

Knife completed and assembled. |

|